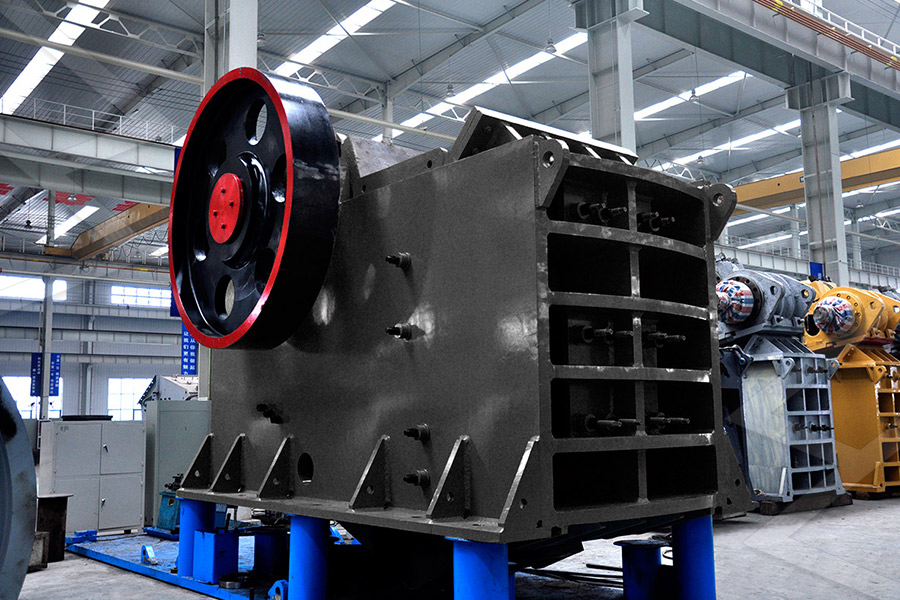

2013 Savying Energy Double Toggle Jaw Stone Crusher

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: singletoggle jaw crushers for a 2017年10月19日 The purpose of this article is to obtain a comprehensive mathematical description of the kinematics of a doubletoggle jaw crusher The driving mechanism of the The kinematics and mechanical advantage of the doubletoggle jaw crusher2023年12月20日 The crushing mechanism of the doubletoggle jaw crusher has been modeled as a planar mechanism with six links and six revolute joints, with the eccentric shaft being The kinematics and mechanical advantage of the doubletoggle jaw crusher2012年10月1日 This paper conducts a comprehensive study on the optimization design for crushing mechanism of double toggle jaw crusher The optimization aim is to reduce Optimization Design for Crushing Mechanism of Double Toggle Jaw Crusher

Optimal energy management for a jaw crushing process in

2014年4月15日 This research provides a new theoretical basis for energy saving operation of crushing station in open pit mine and shows that the energy saving effect of multiparameter The study was carried on a model doubletoggle jaw crusher which allows crushing forces, energy and toggle displacement to be measured The main aim of the work was to determine the ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING 2017年5月1日 There are two main types of jaw crushers, single toggle and double toggle The difference being the resulting motion of the jaw depending on the design (Wills and Napier A fundamental model of an industrialscale jaw crusher2017年1月27日 The study was carried on a model doubletoggle jaw crusher which allows crushing forces, energy and toggle displacement to be measured The main aim of the work Analysis of Energy Consumption of Crushing Processes – Comparison

Analysis of Energy Consumption of Crushing Processes

2017年8月1日 The study was carried on a model doubletoggle jaw crusher which allows crushing forces, energy and toggle displacement to be measured The main aim of the work 2023年2月17日 Jaw crushers are an essential piece of equipment in many industries, including mining, construction, and recycling These powerful machines are responsible for crushing large rocks and other materials into The Ultimate Guide to Replacing Toggle Plates 2010年5月13日 Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipments in mechanical and mining industries As jaw crushers break minerals ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design The kinematic analysis of single [PDF] Computer aided design of jaw crusher Semantic ScholarA line diagram of a double toggle jaw crusher and its main components is Consideration was also paid to important aspects related to other energyconsumption components in technological road A double toggle jaw crusher Download Scientific Diagram

.jpg)

Roljack Asia Limited DOUBLE TOGGLE JAW CRUSHER

DOUBLE TOGGLE JAW CRUSHER (DTO) Stone Engineering Equipment Solution, Steel Cashing Equipment Solution, Construction Equipment Solution, 'AA' Class PWD Contractor Fabrication Industries etc CORPORATE Working Hours Monday Saturday: 09:45AM 06:15PM Sunday Holiday Connect with Roljack Asia Ltd sbm energy saving stone jaw crusher2020 savying energy double toggle jaw stone crusher Equipment Energy Saving single energy saving 15 30 system energy saving more than double Low Noise little dust Jaw crusher parts that contain frame movable and stationary plate bearing eccentric shaft toggle jaw flywheel eccentric shaft belt pulley back moving spring jaw plate mill/sbm energy saving stone jaw crushermd at master mill 10, Burnt Salt Gola Lane, 1st Floor, Howrah – West Bengal, India +918584074698; contact@premurimpex +913326660850Double Toggle Jaw Crusher Premur Impex2010年4月30日 A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields The performance of jaw crusher is mainly determined by the kinematic features (PDF) Optimum design and analysis of (the) swinging jaw

.jpg)

DoubleToggle Jaw Crusher [1] Download Scientific

2023年10月17日 Download scientific diagram DoubleToggle Jaw Crusher [1] from publication: Assessing Efficiency in a unified size reduction plant when reducing large ore into powder particulate matter In Get Mild Steel SAYAJI DOUBLE TOGGLE JAW CRUSHER, For Stone, Capacity: 100 To 400 at best price in Ernakulam, Kerala by New India Tech and more retailers ID: Mild Steel SAYAJI DOUBLE TOGGLE JAW CRUSHER, For Stone2017年10月19日 The purpose of this article is to obtain a comprehensive mathematical description of the kinematics of a doubletoggle jaw crusher The driving mechanism of the crusher is modeled as a planar six bar linkageThe kinematics and mechanical advantage of the doubletoggle jaw crusher2020年7月24日 The Terex® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and low operating costs These rugged machines are manufactured with heavy duty parts for constant operation and long life Our doubletoggle jaw crushers suitable for hard and very hard rocks and abrasive applications Terex® Jaques Jaw Crushers DT JAQUES Terex

Toggle vs Double Toggle Jaw Crushers: Understanding the

On the other hand, double toggle jaw crushers have a complex movement of the moving jaw The motion is generated by two levers, and the moving jaw is hung on the eccentric shaft This design allows for a more uniform crushing action and can handle largerFind here Jaw Crusher, Heavy Duty Jaw Crusher manufacturers, suppliers exporters in India Mild Steel 100 Tph Double Toggle Jaw Crusher ₹ 34,00,000 Get Quote Mild Steel Double Roll Crusher ₹ 9,00,000 Mild Steel Double Jaw Crusher Heavy Duty Jaw Crusher Latest Ultimately, the choice between a single toggle and a double toggle jaw crusher depends on the specific requirements of the application Single toggle crushers are ideal for smaller operations and softer materials, while double toggle crushers are better suited for larger operations and harder materialsExploring the Differences Between Single and Double Toggle 2021年5月17日 In a machine like the jaw crusher, toggle plates are a valuable component that essentially serve as a safety joint and fuse that is attached to the moving jaw A toggle plate basically operates like a fuse If any material enters a jaw crusher that cannot be crushed, whether due to its size or composition, the toggle plate is meant to break Jaw Crusher Toggle Plates vs Hydraulic Toggle Relief Systems

.jpg)

Dynamic Analysis of Double Toggle Jaw Crusher Using

2012年11月17日 The schematic diagram of jaw crusher is shown in Fig 1 Figure 1 Double Toggle Jaw Crusher Schematic Diagram In the traditional design process of mechanical products, hand drawing or computer drawing 2D graphical is often used to express the mechanical parts and assembly relationships, this approach2022年8月22日 double toggle and single toggle Due to its simplicity, lower cost, and its higher efficiency, the single toggle jaw crusher is the most realized form in new applications Jaw crushers achieve size reduction mainly by compressing particles between relatively slow moving, inclined surfaces The material being fed into theSimulation of Energy Consumption in Jaw Crusher Using 2016年7月16日 [Show full abstract] laboratory doubletoggle jaw crusher The obtained results were compared to the energy associated to rock crushing by threeangular tips shape and smooth platesSelected Design Issues of Toggle Plate Selection on the Figure 25: Hardfacing of mild steel with hardfacing insert to form hardfaced jaw (Okechukwu et al, 2018) Figure 26: Exploded view of the pitmanmovable jaw subassembly Figure 27: Fixed jawsupport plate subassembly and exploded view Corresponding author’s email address: okerex2002@yahoo 465 Okechukwu et al: Development of a Laboratory DEVELOPMENT OF A LABORATORY SIZE SINGLE TOGGLE JAW CRUSHER

(PDF) Design and Operations Challenges of a Single Toggle Jaw Crusher

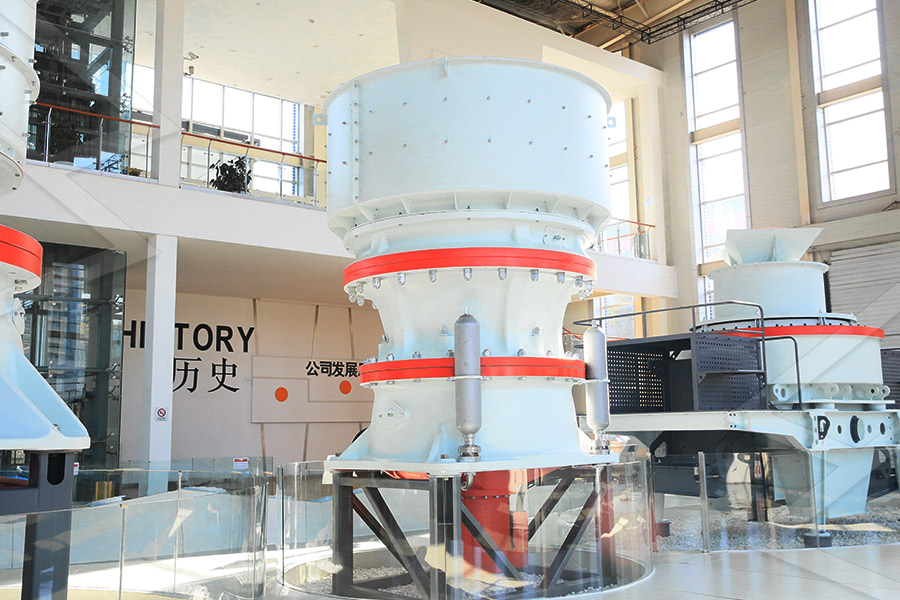

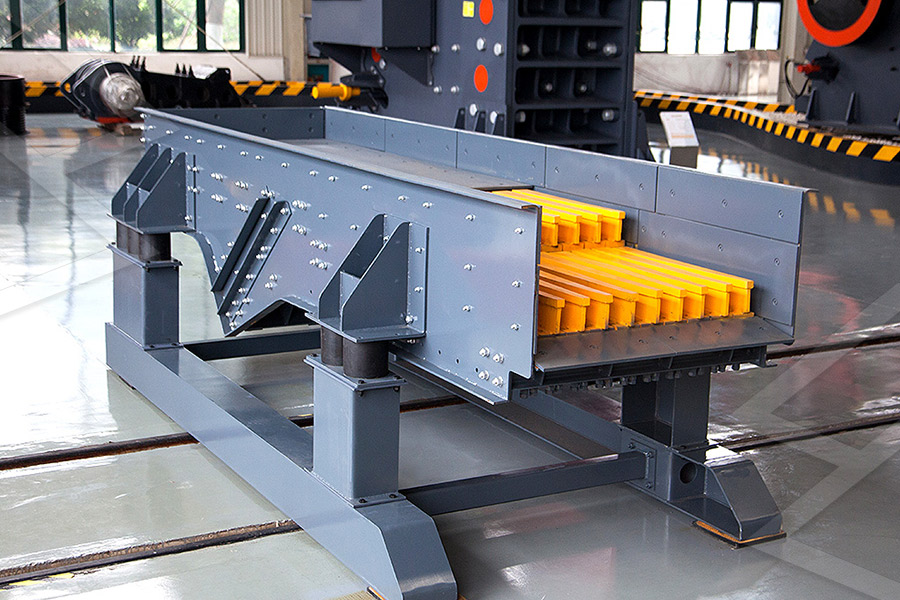

— Jaw crusher is a kind of size reduction machine that is wide utilized in mineral, aggregates and metallurgy fields The interaction between jaw plates and material particles brings the inevitable and high wear to the jaw plates throughout the jaw crusher operation, that not only decreases the efficiency, however also will increase the price and also the energy consumption of the jaw The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber Jaw Stone Crusher Single Toggle vs Double Toggle JXSC 2023年9月5日 Jaw Crushers, Stone Coal Crusher, Belt Conveyor, Bucket Elevator, Apron Feeder 22/10/2013: 5: Tooth Double Roll Crusher: Laxmi Snacks Pvt Limited: 600 x 400: 01 no Nadiad: 3/2/2016: Other INSTALLATION Stone Coal Crusher Double Toggle Jaw Crushers Single Toggle Jaw Crushers Reversible Impactor Vibrating Screen Horizontal Shaft Stone Coal Crusher, Reversible Impactor, Single Toggle Jaw Crusher The study was carried on a model doubletoggle jaw crusher which allows crushing forces, energy and toggle displacement to be measured (2013) suggested that the total energy required to Energy consumption values of each crusher per tonne

Sadguru Stone Crusher, Indore Manufacturer of Double Toggle Jaw

Sadguru Stone Crusher Jhabua, Near Playa Khadhan, Indore, Madhya Pradesh, India2024年10月30日 The Powerscreen Premiertrak 420E Jaw Crusher is a midrange crusher used in recycling, quarrying, and mining applications The crusher features a 1070mm x 760mm (42’’ x 30’’) single toggle jaw chamber As part Learn More about Premiertrak 420EJaw Crusher Premiertrak 400X R400X Powerscreen2024年10月9日 Double Toggle Jaw Crusher Manufacturer As a trusted and renowned double toggle jaw crusher manufacturer, we at Royal Engineering are committed to providing highquality jaw crushers that are built to last Our double toggle jaw crushers are designed to handle the toughest materials and deliver consistent performance, ensuring efficient crushing operations Double Toggle Jaw Crusher Manufacturer Royal Engineering2021年7月20日 Keywords: Finite Element Analysis; Swing Jaw Plates; Jaw Crusher; I INTRODUCTION Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening) Primary jaw crushers are typically of theDesign and Analysis of Swing Jaw Plates of Jaw Crusher

The Ultimate Guide to Single Toggle Jaw Crushers: Structure

2023年2月28日 The kinematics of the single toggle jaw crusher cause an elliptical motion, which causes the material to be crushed between the stationary and movable jaw The single toggle jaw crusher design is simple and reliable, with low production costs compared to other types of crushers including overhead eccentric and double toggle jaw crushers 2021年11月9日 A double toggle jaw crusher is much larger heavier more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers so if one was to upgrade the bearings throughput could be closer to that of a modern difference between single and double toggle jaw crusher2022年3月28日 Trio CT2036 Jaw Crusher Manual (254)pdf Free download as PDF File (pdf), Text File (txt) or read online for free This document provides a parts and operation manual for a CT Series 20" x 36" jaw crusher It outlines various safety hazards and precautions associated with crushing and conveying machinery The manual discusses general safety practices for Trio CT2036 Jaw Crusher Manual PDF PDF Scribd2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, resulting from uneven Optimisation of the swinging jaw design for a single toggle jaw crusher

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 A double toggle jaw crusher is a type of jaw crusher where the moving jaw is suspended from an eccentric shaft that is positioned on the top of the crusher The swing jaw is moved by a cam or pitman mechanism, acting like a lever as it can impact your energy costs Cost: The cost of a jaw crusher is also an important consideration Ensure 2023年12月25日 The crushing mechanism of the jaw crusher with a simple movement of the cheek modeled as a mechanism with five moving links and six rotary joints of the fifth mobility class, with the eccentric Mathematical modeling kinematics of double toggle jaw crusher2024年8月20日 There are several types of jaw crushers available on the market, including singletoggle jaw crushers, doubletoggle jaw crushers, and overhead eccentric jaw crushers Singletoggle jaw crushers are the most common type, and they are designed with a large feed opening and a simple toggle mechanismJaw Crusher Basics in 3 MinutesSBM Industrial Technology Product Description CPC 21610AH Single Toggle Jaw Crusher are High Performance Machines built for Heavy and Continuous Duty Product Specification: Crushing Capacity 15 to 20 TPH Engine Power 35 HP Speed 300 RPM Hard Stone,325 RPM Soft StoneStone Crushing Equipment Single Toggle Jaw Crusher

Jaw Crusher Manufacturer, Single/Double Toggle Jaw Crusher

2017年3月20日 Impact Crusher V TechMakkers offer robust impact crushers that are simple in structure and provide smooth operation They have high crushing efficiency and consume lesser powerThe impact crusher is a widely used equipment in rock mining, stone crushing and quarrying to crush all kinds of ores, bauxite, cement and a variety of mineralsIntroduction: Double toggle jaw crushers are widely used in the mining, construction, and aggregate industries for processing hard and abrasive materials These crushers are known for their high reduction ratios and ability to handle a wide range of feed sizesOptimization Design of Double Toggle Jaw Crusher – stone 2012年10月1日 The purpose of this article is to obtain a comprehensive mathematical description of the kinematics of a doubletoggle jaw crusher The driving mechanism of the crusher is modeled as a planar six Optimization Design for Crushing Mechanism of Double Toggle Jaw Crusher2020年1月1日 Download Citation Static force analysis of a single toggle jaw crusher There are various recommendations in domestic and foreign literature regarding the law of distribution of the crushing Static force analysis of a single toggle jaw crusher

.jpg)

Double Toggle Jaw Crusher at Best Price in India India

Laxmi ms double toggle jaw crusher, capacity: 10 50 tph; Pics international mild steel double toggle jaw crusher, for Mrb mild steel secondary double toggle jaw crusher, for ston Nandhi mild steel double toggle oil jaw crusher, 50 hp; Mild steel 16"x10" (400x250mm) secondary jaw crushers; Sharda industries crushing machine jaw crusher